Industry Alpha、ベトナムにて工場・倉庫のスマート化ソリューションの提供を開始

背景

近年、ベトナムはGDP年間平均8%の急成長を遂げています。若年層が最も多く、現在のベトナムの人口ピラミッドは高度経済成長期における日本の人口ピラミッドと類似しています。

実際、ベトナムでは人件費が十年前に比べて3倍近く値上がりしています。

ベトナムの人件費は今後も上昇傾向にあり、これまでのやり方では生産性を維持することができません。

また、ベトナムでは、若年層の教育レベルの向上により、サービス業やIT業界などの高収益産業に就職する傾向が高まっており、製造・物流業界において労働力不足が懸念されています。

今後ますます加速するであろうグローバル競争に対応するためにも、スマート工場・倉庫の導入を急ぐ必要があると認識し、当社はベトナムにて工場・倉庫のスマート化のソリューションを提供する運びとなりました。

事業内容

当社は、製造・物流業界においてスマート化を推進するスタートアップです。アルゴリズムやロボット・AI技術を活用し、自動化や省力化を図ることで、お客様の生産性向上や品質確保などを支援しています。

当社がパートナーと取り組んできた事例

- 自動梱包ラインシステムの導入による、梱包作業の自動化

- 検査工程をAIカメラで品質向上

- ピッキングと搬送を同時に自動化

ベルトコンベアとアームロボットを組み合わせ、製造ラインの省人化を実現した事例です。

従来であれば作業者が手作業を荷物をピッキングし、箱を組み立て、梱包作業を行っていたところをアームロボットとセンサーにより自動化いたしました。

これにより、多数の荷物の処理を可能にし、大幅な人件費の削減に成功いたしました。

また、検査工程においては、自動化生産ラインにAIカメラを導入することで、品質の向上を図っています。

さらに、従来の倉庫におけるピッキングと搬送作業をスマート化する取り組みでは、

アルゴリズムによってAGVが自動的に最適化された順序でピッキング場所に移動いたします。

人が行う作業はAGVのいる場所に行き、ピッキング及び検品作業を行うのみとなります。

当社のソリューションにより、入庫から出庫までの一連の流れの中で、人が行う作業を大幅に削減するスマート倉庫の実現が可能となっております。

今後の展望

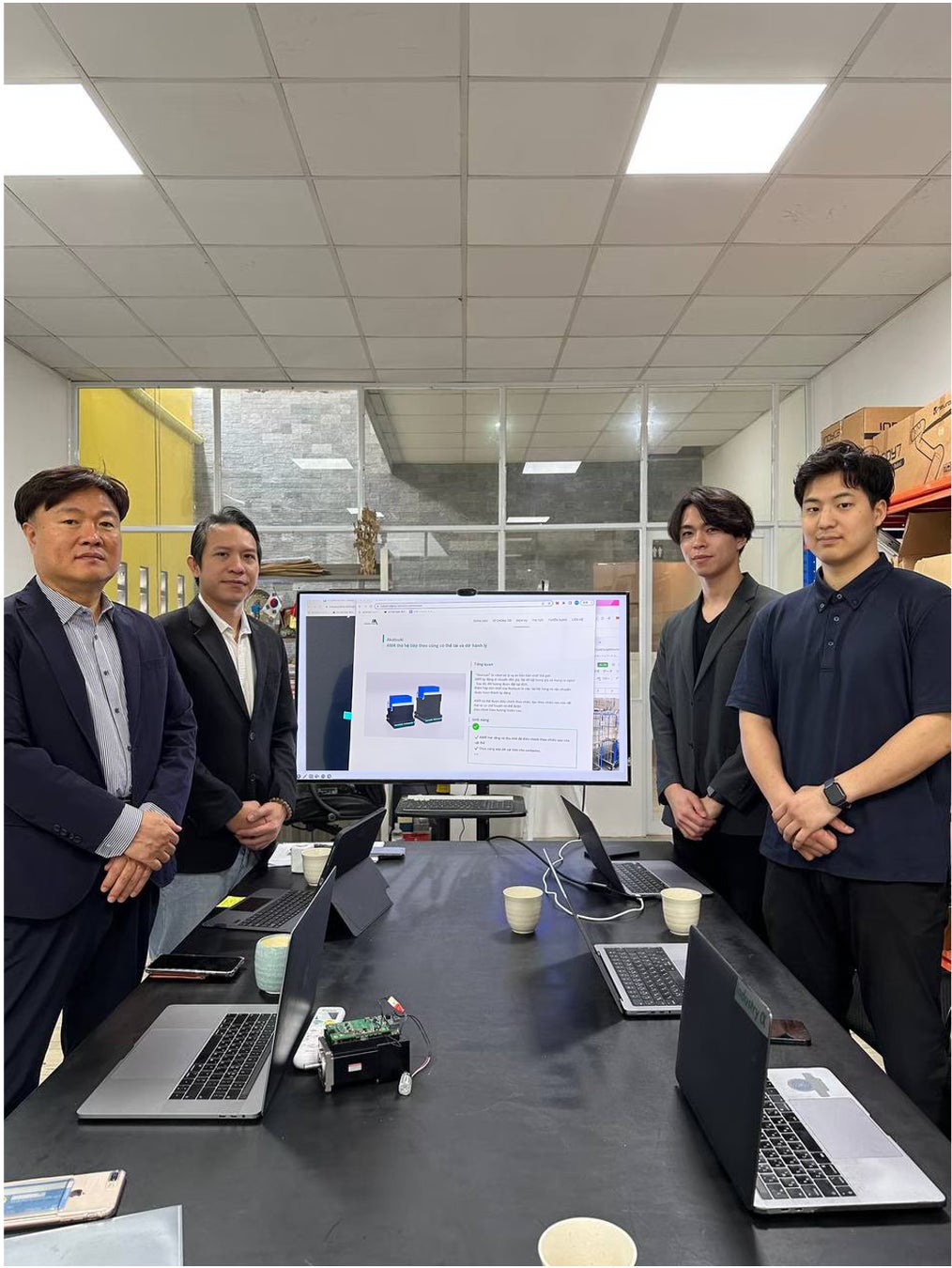

この度、ベトナムのホーチミン工科大学と共同開発の実施を決定いたしました。

これまで、当社自身も大学発ベンチャーとして倉庫・工場における様々な課題解決を実施して参りました。

今後は現地の優秀なホーチミン工科大学の学生とコラボレーションし、ベトナムの製造・物流業界における様々な課題をスマート化することで、省人化・省力化に寄与いたします。

また、当社はスマート化事業をベトナムだけでなく、東南アジア全土にも拡大して参ります。

国連人口基金の報告書によると、2040年までに、ヨーロッパ諸国の一部とアジア諸国が65歳以上の人口が30%以上の国になると予測されており、21世紀は高齢化の世紀とも呼ばれています。

今後は、アジア全域での事業展開において、日本で培った深い知見と最先端技術を活かし、10年後を見据えた多角的な解決策を提供していく所存です。