Industry Alphaは、梱包工程のスマート化を実現する「自動梱包ラインシステム」の提供を開始いたします

サービス提供の背景

近年、東南アジア諸国では、インフラ整備が進み、経済成長が加速しているため、人件費が年々高騰しています。

また、経済成長に伴いユーザー体験の向上が求められており、品質管理の観点から品質の向上を求める声が上がっています。

企業は生産性の向上を目指し、省人化と品質改善を重要な事業戦略として掲げており、東南アジア地域における工場・倉庫のスマート化に対する需要が高まっております。

当社は、このような背景から自動化やロボット化などのスマート化事業を東南アジア全土に拡大することで、人件費の削減や生産性の向上を実現し、製造・物流業界に貢献いたします。

自動梱包ラインシステムの概要と3つの特徴

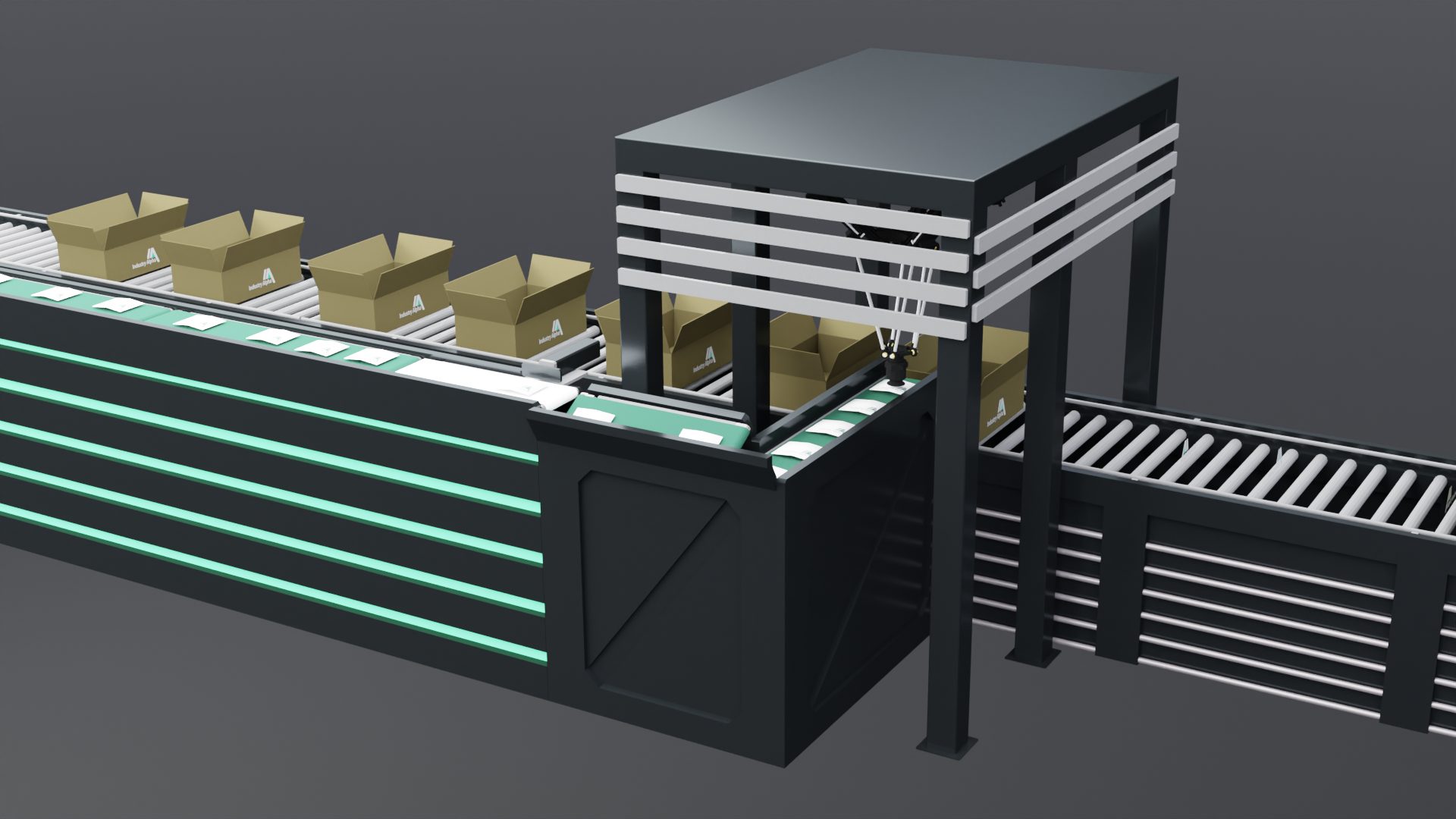

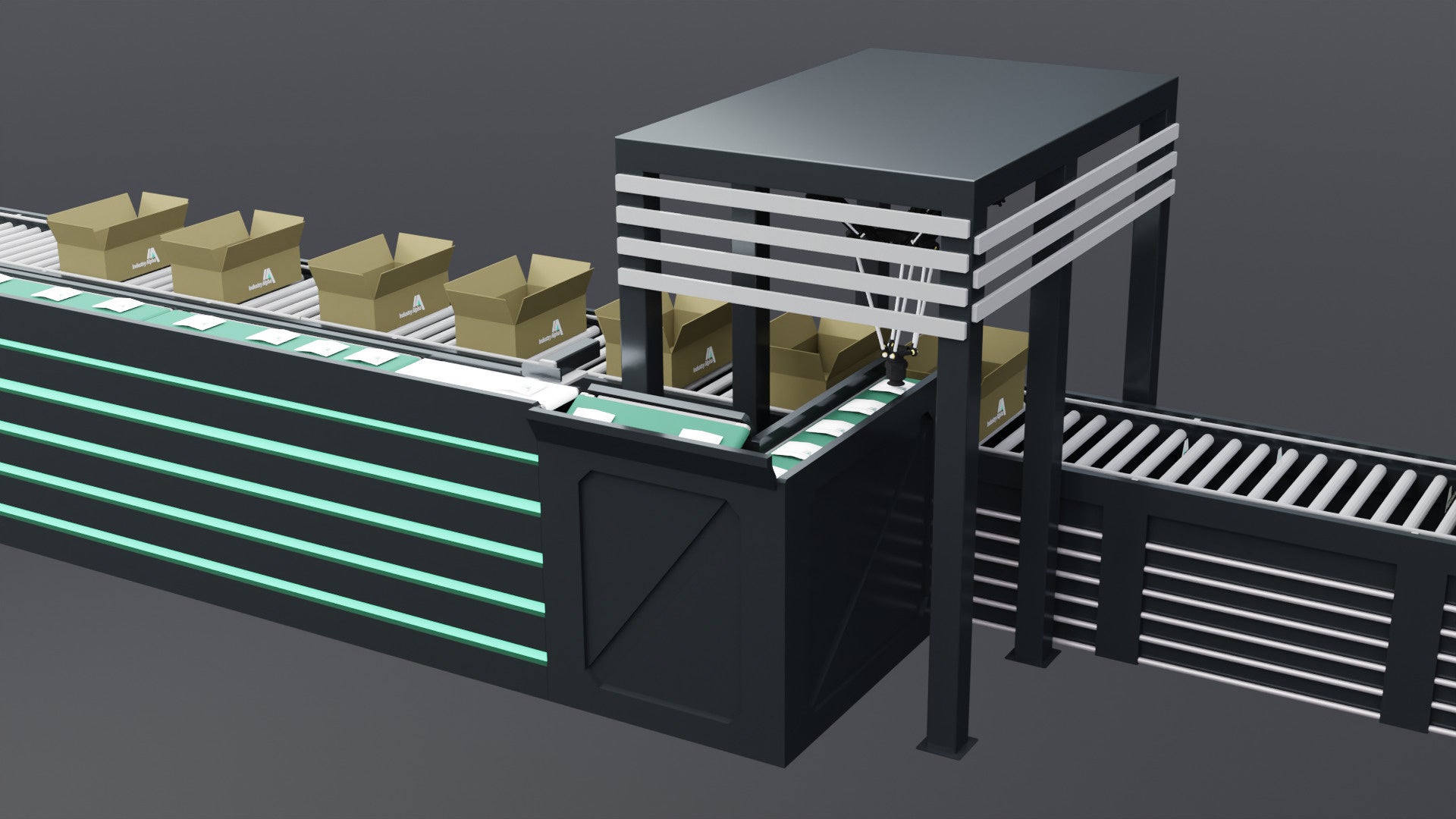

工場における梱包工程を自動化するシステムです。

このシステムは自動で段ボール箱の組み立て、折り畳み、製造年月日の印刷を実行いたします。また、オプションで、投入された荷物の重量を確認し、過不足を排除することも可能です。高度なセンサーシステムを用いて製品の欠品を監視し、製品の品質と一貫性を確保いたします。

詳細は下記よりページよりお問い合わせください

3つの特徴

- 自動で多数の荷物を処理

- SKUを素早く、簡単に切り替え可能

- 梱包工程の完全自動化で人件費を削減

導入効果

当社のパートナーと製菓業界における梱包ラインの自動化を実現した事例です。

ベルトコンベアから流れてくるお菓子を、アームロボットが自動でピックし、自動で段ボール箱を組み立て・梱包までを実施いたします。

これまで、菓子類、ダイエット食品などの生産・販売輸出を手掛ける工場では下記のような手順になっていました。

- ベルトコンベアから流れてくるお菓子を人がピッキングする

- 段ボール箱を組み立てる

- 梱包する

- テープで箱を止める

- 製造年月日を記入する

自動梱包ラインシステムの導入により、梱包工程を3stepに改善いたしました。

- ベルトコンベアから流れてくるお菓子をバケットコンベヤにて5袋を1パックに仕分け

- 自動製函機によって段ボール箱の形成

- ロボットによる荷物の箱詰めを実施し、製造年月日を印刷する

Before

●梱包ラインに多くの人手が必要

●繰り返し作業により人為的なミスが発生

●人の手により作業効率が変動

After

●全ての商品梱包をワンストップで対応

●コンベアやアームロボットと連携し無人化を実現

●時間あたりの作業効率の向上

今後の展望

このシステムは、高い生産性と効率性を実現し、従業員の負担を軽減を実現いたします。

東南アジア地域においては、製造業の成長が著しく、スマート化による生産性の向上が求められています。

当社は自動梱包ラインシステムによる自動化ソリューションの導入により、人件費の費用対効果が難しい東南アジア地域における製造業の省人化において、お客様のコストメリットを実現できる自負がございます。

センサーによる品質管理で製品の欠品を無くし、アームロボットと自動製函機にて梱包を自動化することで、品質改善と省人化を実現いたします。

当社は、東南アジアの各国において、販売代理店やパートナー企業との提携を進め、製造業の生産性向上に貢献することを目指します。