【Optimization Algorithm × AGV】Industry Alpha Co., Ltd. Optimizes Multi-AGV Operation through Introduction of Swarm Control Module

Swarm Control Module

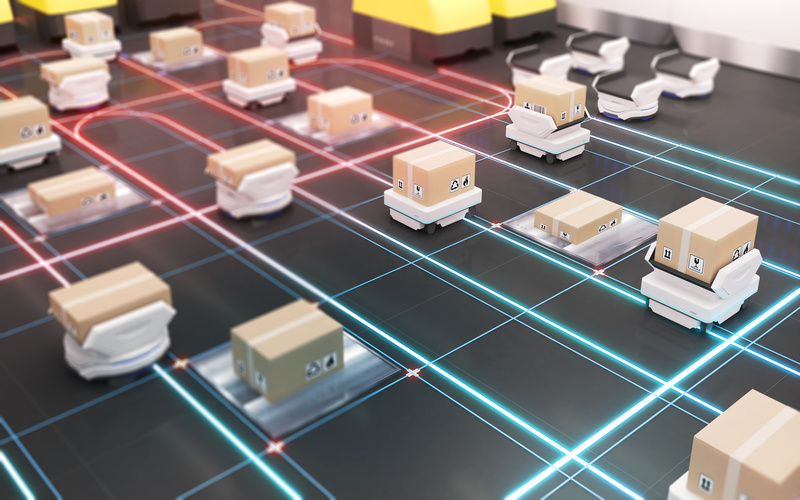

The swarm control module enables optimal control of multiple AGVs and is a system that applies the technology called swarm control, where multiple AGVs coordinate and operate together in the same work area.

Recently, it has attracted attention in the manufacturing and logistics industries for its potential to improve operational efficiency and productivity of unmanned transport vehicles.

By using swarm control, each AGV/AMR shares information such as position, speed, and direction, calculates the shortest possible transport route, and achieves route optimization.

Challenges When Operating Multiple AGVs and AMRs

When operating multiple AGVs and AMRs simultaneously, various issues can arise.

Although AGVs are introduced to reduce labor in transportation, problems such as AGVs stopping as they face each other or taking detours often occur. Below are common issues frequently encountered in the field:

- Intersection Control Issues: Optimizing communication between transport units at intersections

- Map Integration Issues: Optimal route navigation through integrated overall maps

- Battery Life Issues: Energy-saving operation through route optimization

Intersection Control Issue: Optimizing communication between transport units at intersections

When multiple units operate in the same area, it is necessary to set rules to avoid collisions at intersections and between vehicles.

AGVs communicate with each other just before entering an intersection, exchanging information such as their planned routes and estimated entry times. The cloud server can monitor the situation within the intersection in real-time, allowing it to adjust routes and entry timings as needed.

This reduces unnecessary waiting times at intersections and enables more efficient operation of the automated guided vehicles.

② Map Integration Issue: Optimal Routing through Unified Maps

When operating multiple AGVs, it is necessary to accurately track the location of each vehicle and automatically calculate optimal routes.

When multiple AGVs pass through the same area, each vehicle individually performs self-localization and map creation, building a local map. However, relying solely on these local maps makes it difficult to consider the movements and relative positions of other AGVs, complicating optimal control of the entire system.

To solve this, local maps recognized by multiple AGVs are integrated to generate a unified overall map. This allows sharing of positions and routes among all vehicles, enabling optimal control.

③ Battery Life Issue: Energy-Efficient Operation through Route Optimization

Since AGVs and AMRs run on batteries, their operating time is limited.

When operating multiple AGVs, it is necessary to manage the placement of charging stations and coordinate charging schedules. Using group control, multiple AGVs operating simultaneously can optimize their routes more efficiently than if operated individually. By running AGVs along optimal routes, energy-efficient operation is achieved, thereby extending battery life.

By leveraging the group control module, optimal operation of multiple AGVs is made possible.

Implementation of Group Control Module

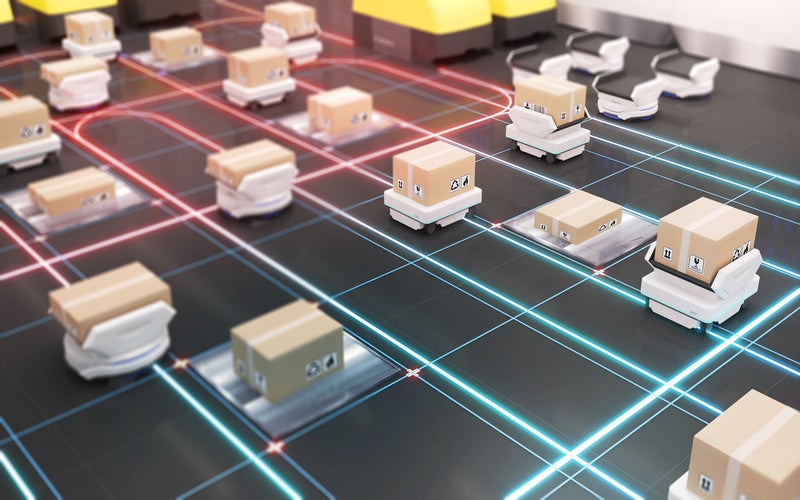

We have introduced six picking-assist AGVs in the picking area of our logistics warehouse.

In the picking area, AGVs automatically move to the picking locations, and after a person picks the items, they place the items onto the AGV, which then completes the transportation.

Normally, increasing the number of AGVs would raise costs and cause issues such as detours due to obstacle avoidance. However, by utilizing the group control module, we have achieved optimal operation of multiple AGVs.

Particularly in this warehouse, where humans and AGVs work together, the group control module enabled smooth sharing of position information between AGVs and ensured they travel via the shortest routes within the area.