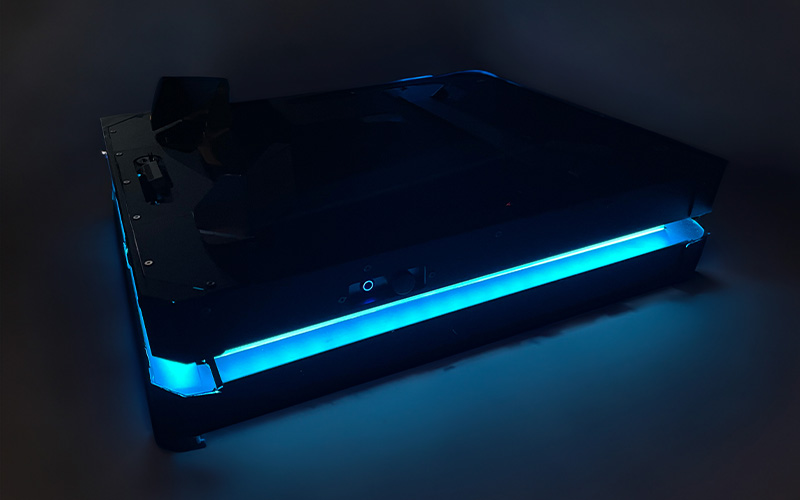

[1000kg payload AMR] Industry Alpha begins introducing a new heavy-duty AMR to contribute to the automation of factories and warehouses

Supporting the realization of smart factories and warehouses with a slim, compact 1,000 kg transportable AMR that is ideal for Japanese worksites

Industry Alpha Inc. (Head office: Itabashi-ku, Tokyo; CEO: Takumi Watanabe; hereinafter referred to as “Industry Alpha”), which develops smart factory and warehouse businesses, has begun introducing a new 1,000 kg payload model of Kaghel (AMR), contributing to further automation in the manufacturing and logistics industries.

Development Background

Due to the decline in the working population caused by the declining birthrate, Japan’s manufacturing and logistics industries are facing the need for automation. In particular, in factories and warehouses that handle heavy objects, a labor shortage is expected due to a decrease in forklift operators and workers. However, in the context of automated transportation of heavy objects, a dilemma has arisen in that it is difficult to ensure safety and to advance automation.

A series of tasks such as loading and unloading materials from trucks, transporting them to their destination, and storing them are carried out in spaces where people, forklifts, and heavy transport vehicles pass by, making it difficult to ensure human safety and eliminate the possibility of collisions, and automation has not progressed.

In addition, in factories and warehouses with many narrow spaces, automating the transportation of heavy objects has also been difficult from the perspective of size. Heavy-duty AGVs/AMRs, which tend to have larger standards, may not fit the Japanese on-site environment.

To address the above issues, Industry Alpha, an industry leader in the development and implementation of domestically-made AMRs (autonomous driving robots) for factories and warehouses, has begun implementing Kaghelo’s new 1,000kg payload model as an AMR optimized for Japanese factory and warehouse environments, based on its know-how in extracting needs from the field and its safety design capabilities cultivated through its implementation track record, with the aim of further automating the manufacturing and logistics industries.

Features of Industry Alpha’s Kaghel (1000kg carrying capacity model)

① Thin and compact body ideal for Japanese factories and warehouses

With a thickness of 210 mm, it can slip under objects being transported, such as basket carts. This minimizes the effort required to process the transport cart.

In addition, the compact design, with a width of 800 mm and a total length of 900 mm, allows for smooth travel even in Japan’s many narrow spaces.

② Safety design based on collaboration with humans

Safety is essential when transporting heavy objects in factories and warehouses, where collaboration between humans and machines is a given. In order to realize an AMR that can truly collaborate with humans, we have reexamined safety design from the perspectives of sensing, lift-up, and emergency stops.

Sensing function To detect people, machines, and obstacles, the robot is equipped with two LiDAR sensors in the front and one in the rear that use infrared rays to detect surrounding objects, allowing for 360° recognition of the surroundings. A LiDAR sensor compatible with PL.d is used.

Lift-up function: A mechanism that mechanically synchronizes the lifting height of the lifter is introduced to ensure stability during lift-up and lift-down.

Wireless emergency stop function: The receiver of the PL.d-compatible wireless emergency stop button is directly connected to the drive unit (motor driver).

③ Flexible linkage with peripheral devices

Industry Alpha designs and develops its own AMR and AMR control software (FMS) in-house, and provides SI for each site.

This FMS allows AMRs to be controlled in groups while also achieving smooth and flexible linkage with peripheral devices and higher-level systems. For example, by linking with manned forklifts, the forklift is responsible for loading/unloading and the AMR is responsible for transportation, we will link with peripheral devices to promote automation that makes the most of existing equipment.

Past examples of initiatives: Linkage with forklifts (manned/unmanned) Linkage with welding machines and press machines (PLC control) Linkage with production planning systems Linkage with AGVs/AMRs made by other companies

Case study: Major automobile parts manufacturer

Here is an actual case of Kaghel’s 1000kg payload model being used by a major auto parts manufacturer. By introducing Kaghel, this client was able to efficiently transport special carts weighing up to 1000kg, reducing the number of forklift workers, and achieving factory automation and efficiency.

In the past, when transporting heavy objects, the transport area of forklifts and the area where carts were transported by hand overlapped, and there were issues with ensuring safety and efficiency in the field when transporting heavy objects.

① Reduction in forklift workers/pallet carriers

By introducing AMR, forklift workers can concentrate on loading and unloading pallets. In addition, pallet transportation in the front and rear processes is also automated, reducing the number of forklift workers and pallet carriers by four people in total.

② Improved safety

It was difficult to ensure safety because forklifts and people were coming and going, but safety is ensured by changing the speed of the AMR depending on whether it is loaded/unloaded and whether it is inside/outside the area where the forklift is located, and by using melodies to alert forklift workers.

Future developments

Kaghelo aims to expand its lineup of aircraft to accommodate a variety of use cases. It plans to expand its product lineup that contributes to on-site automation, including the development of a 1500kg model, and also plans to release a 2000kg model. Advance inquiries are accepted on our website.

- [AMR for retail industry x cutting-edge FMS] FUJI and Industry Alpha collaborate to conduct demonstration experiments to contribute to automation in the retail industry

- [Manned forklift x AMR] Industry Alpha begins analyzing existing forklift operations in Asahi Soft Drinks' logistics center to automate operations using AMR