【1000kg Payload AMR】Industry Alpha Begins Deployment of New Heavy-Duty AMR to Enhance Factory and Warehouse Automation

Supporting Smart Factories and Warehouses with a Slim, Compact 1000kg Payload AMR Optimized for Japanese Worksites

Industry Alpha Inc. (Headquarters: Itabashi-ku, Tokyo; CEO: Takumi Watanabe), a company engaged in smart factory and warehouse automation business, has begun deploying the new 1000kg payload model of its Kaghelo AMR, contributing to further automation in the manufacturing and logistics industries.

Background of Development

Due to the declining working population caused by Japan’s decreasing birthrate, the manufacturing and logistics industries face an urgent need for automation. In particular, factories and warehouses handling heavy loads are expected to experience labor shortages caused by a decline in forklift operators and workers. However, in the context of automated heavy load transport, ensuring safety has been challenging, creating a dilemma that has hindered progress in automation.

A series of tasks such as unloading materials from trucks, transporting them to their destination, and storing them take place in spaces shared by people, forklifts, and heavy transport carts. Ensuring human safety and eliminating the risk of collisions in these shared spaces is difficult, which has impeded automation efforts.

Furthermore, the many confined spaces found in factories and warehouses make automating heavy load transport difficult from a size perspective. Heavy-duty AGVs/AMRs tend to become larger and may not fit well with the typical Japanese site environment.

To address these challenges, Industry Alpha, a leader in the development and implementation of domestic AMRs (autonomous mobile robots) for factories and warehouses, has leveraged its expertise in extracting on-site needs and its proven capabilities in safety design from past implementations. Based on this, Industry Alpha has launched a new 1000kg payload model of its Kaghelo AMR, optimized specifically for Japanese factory and warehouse environments, aiming to further advance automation in the manufacturing and logistics sectors.

Features of Industry Alpha’s Kaghelo (1000kg Payload Model)

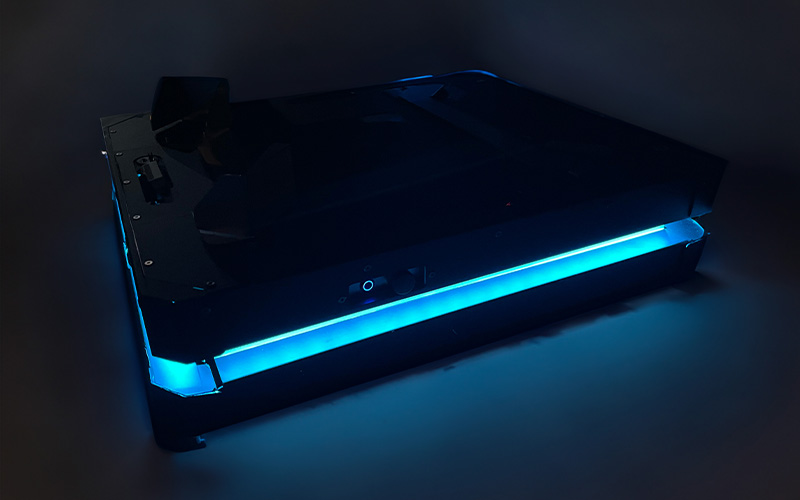

- Thin and compact design optimized for Japanese factories and warehouses

With a thickness of 210mm, it can slide under transport carts such as basket carts, minimizing the need for modifications to the carts.

Additionally, its compact size—800mm wide and 900mm long—enables smooth operation even in the confined spaces common in Japanese facilities. - Safety design based on collaboration with humans

Ensuring safety is essential when transporting heavy loads in factories and warehouses where humans and machines work together. We have reexamined safety design from the perspectives of sensing, lift-up, and emergency stop to realize truly collaborative AMRs.

- Sensing functions: Equipped with PL.d-compliant LiDAR sensors using infrared to detect people, machines, and obstacles, with two sensors facing forward and one backward, enabling 360° recognition of surroundings.

- Lift-up function: Implements a mechanical synchronization mechanism for the lifter’s raising height, ensuring stability during lift-up and lift-down operations.

- Wireless emergency stop: The receiver for the PL.d-compliant wireless emergency stop button is directly connected to the drive unit (motor driver).

- Flexible integration with peripheral equipment

Industry Alpha independently designs and develops both the AMR and its control software (FMS), customizing system integration for each site.

This FMS enables coordinated control of multiple AMRs and smooth, flexible integration with peripheral devices and higher-level systems. For example, it can coordinate with manned forklifts where forklifts handle loading/unloading and AMRs handle transport, promoting automation that maximizes the use of existing equipment.

Past collaboration examples include:

- Coordination with forklifts (manned/unmanned)

- Integration with welding machines and press machines (PLC control)

- Integration with production planning systems

- Cooperation with AGVs/AMRs from other manufacturers

Case Study: Major Automotive Parts Manufacturer

As an example of the introduction of Kaghelo’s 1000kg payload model, we present its use at a major automotive parts manufacturer. By implementing Kaghelo, this client efficiently transports special carts weighing up to 1000kg, reducing the number of forklift operators and achieving factory automation and efficiency improvements.

Background

Previously, the forklift transport area and manual cart transport area overlapped during heavy load transportation work, posing challenges in ensuring safety and efficiency on site.

Benefits of AMR Introduction

Improvement of safety

Since forklifts and personnel frequently crossed paths, ensuring safety was difficult. The AMR adjusts its speed based on load/no-load status and whether it is inside or outside forklift operating areas. Alerts such as melodies are used to notify forklift operators, thereby ensuring safety.

Reduction of forklift operators and pallet handlers

By introducing the AMR, forklift operators can focus on loading and unloading pallets. Additionally, pallet transport in preceding and succeeding processes is automated, resulting in a total labor reduction of four personnel, including forklift operators and pallet handlers.

Future Developments

Kaghelo aims to expand its lineup of models to accommodate various use cases. This includes the development of a 1500kg model and an extended range of products that contribute to on-site automation. The release of a 2000kg model is also planned. Inquiries can be made in advance through our company website.