SERVICE– AI・ロボティクス・数理アルゴリズムを活用した工場・倉庫のスマート化 –

Kaghelo

現場視点から生まれた実用性No.1AMR

概要

柔軟性に優れたAMRで、低い機体の為、かご車への潜り込みも可能です。独自設計のためハードウェア、ソフトウェア両面でのカスタマイズに対応可能です。

特徴

✔️最薄185mmと様々な搬送物等に対応可能な低床型性

✔️高い安全性を実現するための独自設計と国内製造

✔️磁気テープ等の敷設がいらないSLAM走行型

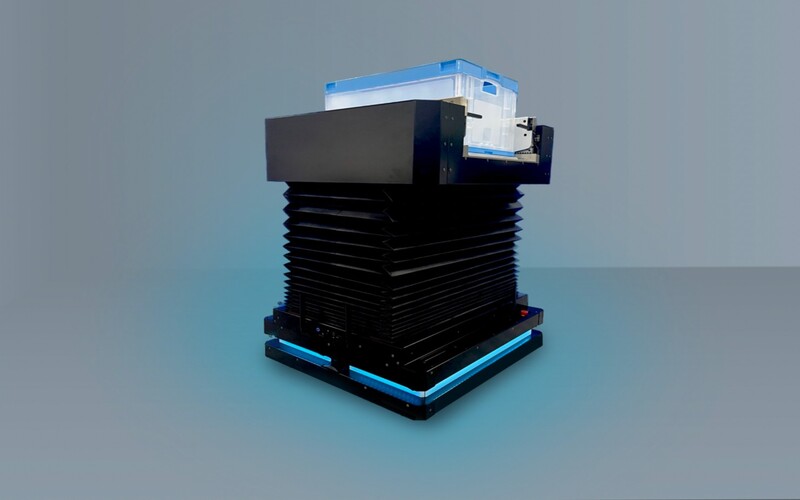

Akatsuki

荷物の出し入れも可能な次世代AMR

概要

「Akatsuki」は世界最先端のケースハンドリングロボットです。

自律的にAMRが棚まで移動し、棚の中の対象物を掴み、搬送を実行いたします。そして、搬送先へ対象物を配置します。Akatsukiの最大の魅力は全自動で出し入れと搬送が完了することです。対象物の高さに合わせてAMRが縦方向へ、移載機構が前後方向に伸縮することで調節する為、専用の荷物や専用の棚を作成するなどのカスタマイズが必要ありません。

特徴

✔️対象物の高さに合わせるためAMRが伸縮して調整

✔️画期的なコンテナ等の荷物の出し入れ機能

✔️出し入れと搬送を1台で担当し全自動化を実現

アーム連携AMR

ロボットアームと連携可能な自律走行搬送ロボットセット

概要

AMRにロボットアームを組み合わせることで、搬送とピックアップ・設置作業を自動化するソリューションです。パーツ供給、仕分け、積み付けなど、人手を介していた工程の無人化を可能にします。

特徴

✔️メーカー問わずロボットアームと組み合わせ可能

✔️走行・動作の両面で効率的なシステムを構築

✔️FMSや外部システムと高い接続性

Alpha-FMS

複数台のAMRの最適制御やエレベーターなど他機器と連携

概要

AMR / AGVの複数台制御、様々な周辺機器やソフトウェアと連携可能なマネジメントシステムです。接続性と拡張性に優れており、お客様のニーズに合わせた仕様でご提供が可能です。

特徴

✔️配車制御、経路生成、交差点制御により複数台を制御

✔️ユースケースに応じてルールや条件を追加して拡張可能

✔️既存設備やアームロボットなどと連携可能

ロケーション管理システム

物の保管場所を管理するシステム トレーサビリティに有効活用

概要

工場や倉庫内の物品や搬送対象の位置を把握・管理するシステムです。RFIDやセンサ等を使って位置情報を可視化し、在籍管理や搬送の最適化に活用されます。

特徴

✔️対象物や搬送物の現在位置の可視化

✔️エリアごとの在庫、資材配置の管理

✔️履歴データに基づくトレースや分析

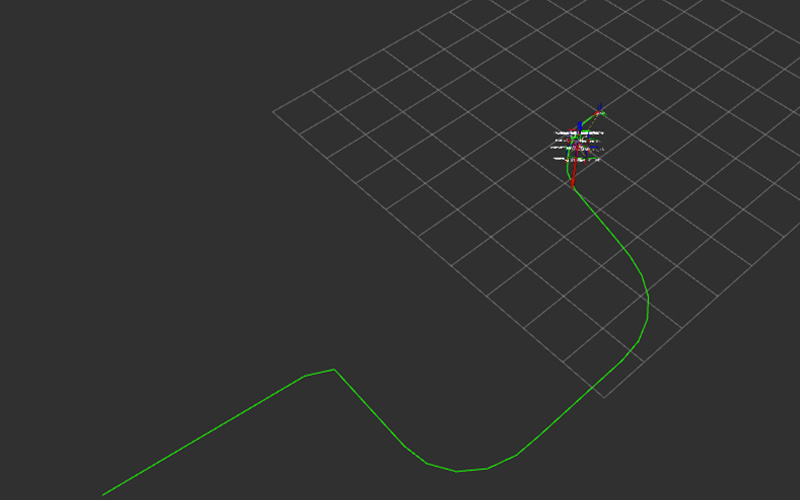

Alpha-NavKit

AMRの自律走行ソフトウェアキット

概要

AMRのSLAM式の自律走行を可能にするソフトウェアです。基本セットとしては、LiDARセンサーとソフトウェアをご提供し、クライアント様独自のハードウェアと組み合わせての運用を想定しております。社内でAMRを内製されたいという企業様のご要望に沿って、コンサルティングやキッティングも含めてご提供しております。

特徴

✔️クライアント内製の機体ハードウェアと組み合わせ可能

✔️センサー取り付けとソフトウェアのインストールで実現可能

✔️取り付ける際の簡易なコンサルティングも実施

ピッキング順序最適化モジュール

アルゴリズムで「歩行」の時間を最小化

概要

ピッキングオーダーを最適な順番にするアルゴリズムです。出荷の際に発生するピッキングオーダーをどの順番で、どの作業者もしくはロボットが取り組むと最も効率的にタスクをこなすことができるか計算します。

アルゴリズムを導入するのみで、ピッキング効率を飛躍的に向上させることが可能です。

特徴

✔️属人的に管理していたピッキングオーダーを最適化

✔️低価格で高パフォーマンスの効率化

✔️ピッキングデータの分析で「手間の可視化」を実現

生産計画最適化モジュール

誰でもワンクリックで生産計画をプランニング

概要

誰でも簡単に生産計画を立案・管理できるシステムです。

作業員の方が属人的に行われている「負荷ならし」をAIが最適化いたします。生産計画のデータ分析により最適な発注・生産・在庫管理業務を可能にいたします。

製造におけるROIを明確にし、コスト削減に寄与いたします。

特徴

✔️誰でもワンクリックで生産計画をプランニング

✔️最も効率のいい計画をAIが自動で作成・管理

✔️使いやすい・見やすいUI

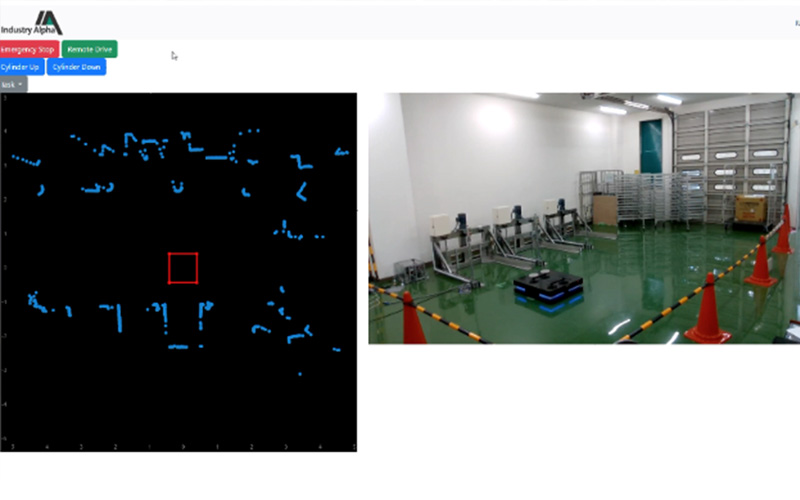

遠隔操作システム

デパレタイジング/パレタイジングを簡単に

概要

ロボットにエラーが起きてしまった際に、遠隔操作にて復帰することが可能なシステムです。

直観的な操作を可能にするUIを導入し、どなたでも簡単にAMRを制御することが可能となっております。

特徴

✔️第三者視点のカメラとセンサー情報を確認

✔️Wi-Fiや5G等の通信形態を問わず実施可能

✔️直感的なUIでリアルタイム操作が可能

作業分析システム

ロボットを適切な通信を用いて遠隔で操作

概要

工場・倉庫内で、人が実施している搬送作業の稼働効率を分析するシステムです。具体的にはフォークリフトにセンサーを取り付けて、走行状況やビートマップなどを可視化いたします。倉庫など、環境側へのセンサーの取り付けが必要ないため手軽に導入することができます。

特徴

✔️既存のフォークリフトにセンサーキットを取り付け

✔️稼働内容や位置情報等のデータを取得

✔️取得結果を元に自動化効果の分析

スマート化コンサルティング

倉庫・工場内物流の自動化ロードマップ策定

概要

工場や倉庫のスマート化に関わるコンサルティングサービスです。

スマート化の全体ロードマップを描いた上で、ステップを策定いたします。複数の部署や工程で自動化を取り組みたいが、実現可能性や費用対効果の程度が分からない企業様へご提供いたします。

特徴

✔️オペレーションの改善提案

✔️ライン自動化に関わる技術調査・費用算出

✔️倉庫内の人材配置や現場設計

システム導入コンサルティング

ニーズや選定基準を明確化

概要

既存製品の選定や導入サポート、パートナー企業と協力したSIなどを実施いたします。技術面や拡張性、使用感など様々な観点で比較検討を行います。DXに取り掛かる場所は決定しているが、どのプロダクトが自社にマッチしているか不明確であり、第三者の立場で検討のサポートを求めている企業様へご提供いたします。

特徴

✔️手間な作業や連絡をアウトソース

✔️選定を通して専門知識や業界知識を習得

✔️システム再構築による業務の最適化支援